By controlling the content of tungsten we can adjust its coefficient of thermal expansion cte to match that of the other materials such as ceramics al2o3 beo semiconductors si and kovar etc.

Copper tungsten rod uk.

Preparation of alloy powder metallurgy method has good electrical and thermal conductivity good high temperature strength and a certain plasticity.

We are also a supplier of high quality copper tungsten heat sinks.

Copper tungsten rod is an alloy composed of the tungsten element and copper element copper content in alloy is commonly occupy an amount of 10 to 50.

Tungsten copper rod conforms to astm b702.

It is refined by hydrostatic molding high temperature.

The microstructure is therefore rather a metal matrix composite instead of a true alloy.

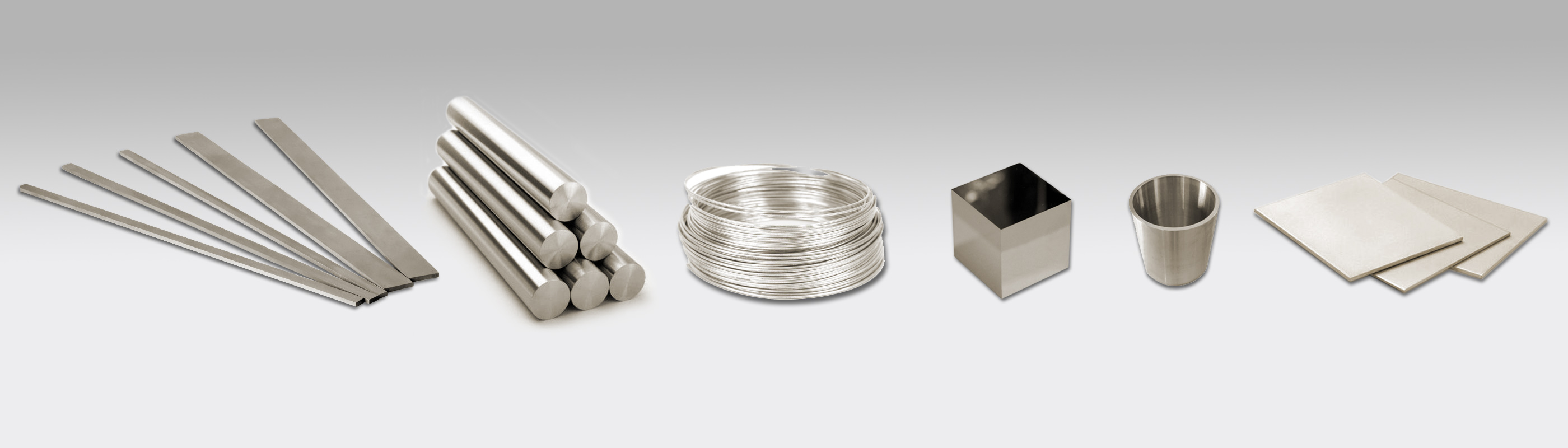

We are capable of producing copper tungsten plates and sheets with a range of thickness from 2 inches to less than 0 004 inches.

Copper tungsten tungsten copper cuw or wcu is a mixture of copper and tungsten.

On the other hand tungsten copper rods 50 50 60 40 and 70 30 present a high thermal and electrical conductivity and high machinability.

We also offer copper tungsten rods with diameters ranging from 0 029 to 5 0 or more.

It s perfect for machine shops research and development diy ers and labs.

We are now capable of producign tungsten copper rods with a range of diameter from 0 029 inches to 5 0 inches or more.

This kind of copper tungsten rod is an alloy composed of tungsten and copper and the copper content of the commonly used alloy is 10 to 50 itis a composite material which is refined by the techniques of high purity tungsten powder and the plasticity and high electrical conductivity of high purity copper powder.

The copper tungsten round rod is ground to achieve the precise shape and size meets american welding society rwma class 10 specifications and has a precision tolerance.

Our tungsten copper product range includes copper tungsten rod foil sheet plate tube tungsten copper rod and machined parts.

Chemetal usa is a recognized manufacturer and supplier of high quality tungsten copper rods.

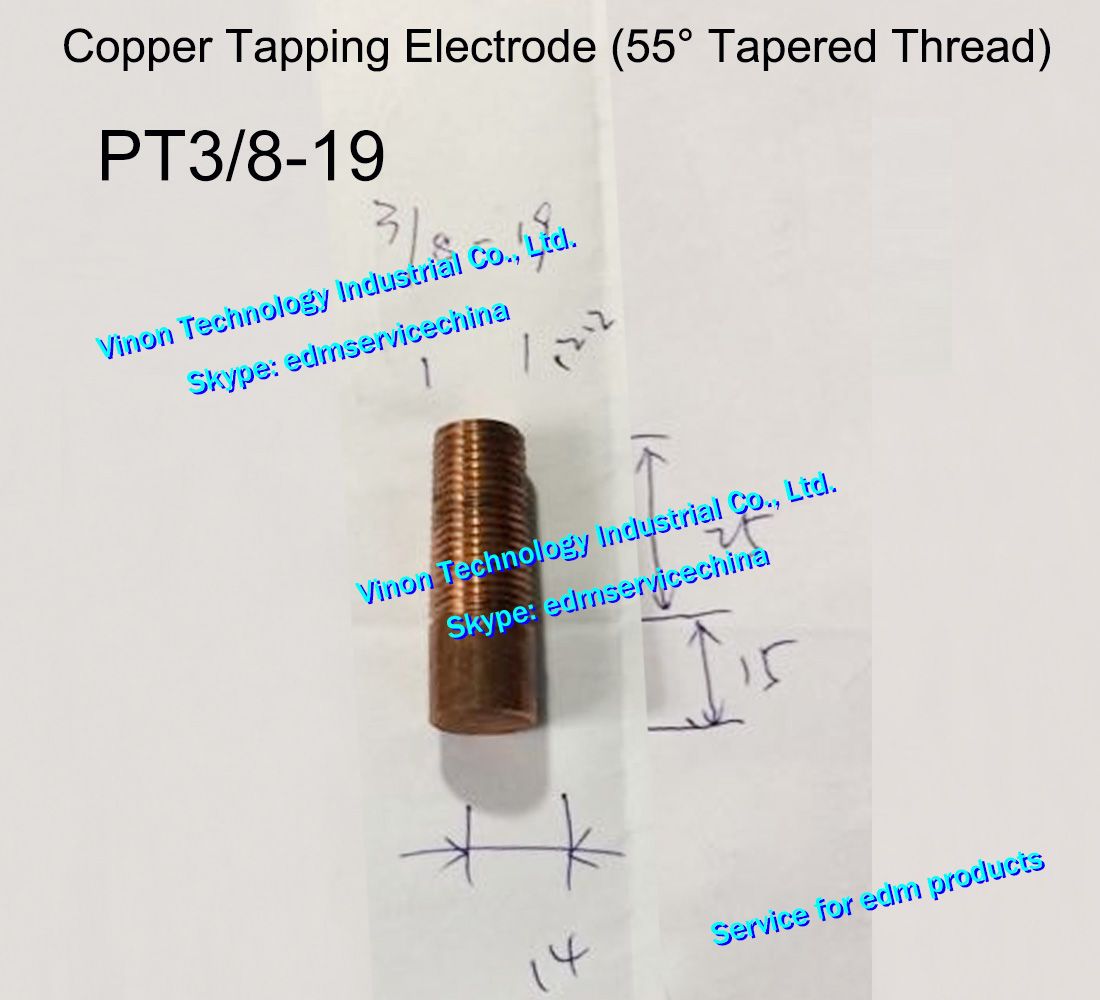

Copper tungsten provides high wear resistance electrical and thermal conductivity and corrosion resistance can be widely used for edm welding electrical resistance welding.

Tungsten copper alloys are useful for their low thermal expansion high wear resistance low consumption high arc resistance and high thermal and electrical conductivity.

As copper and tungsten are not mutually soluble the material is composed of distinct particles of one metal dispersed in a matrix of the other one.